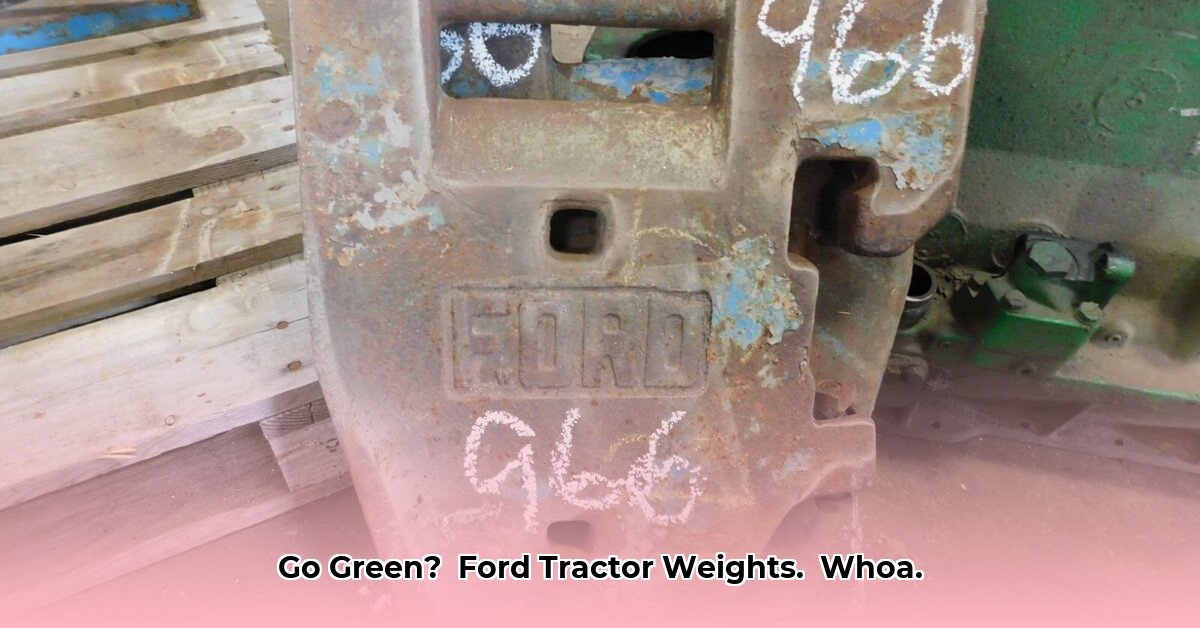

Ford Tractor Weights: A Greener Approach to Farm Efficiency

The ubiquitous Ford tractor weights, essential for stability and efficient operation, present an often-overlooked environmental challenge. This article explores the environmental impact of legacy tractor weights and proposes sustainable solutions for farmers, suppliers, original equipment manufacturers (OEMs), and governments. We'll examine the current market, analyze environmental risks, and outline actionable steps toward a greener agricultural future. For more information on Ford industrial tractors, see this page.

The Unexpectedly Large Market for Older Tractor Weights

A surprisingly robust market exists for older Ford tractors and their associated weights. Websites like TractorHouse consistently demonstrate high demand for these models, indicating their continued use on farms nationwide. Major suppliers such as Taylor Foundry corroborate this, highlighting the scale of the environmental challenge posed by these weights. This persistent demand underscores the urgent need for sustainable solutions.

Environmental Concerns: Weighing the Options

Traditional tractor weights, typically made from cast iron or steel, entail significant environmental costs. Their manufacturing consumes considerable energy and generates greenhouse gas emissions. Furthermore, the recycling rate remains disappointingly low, and comprehensive lifecycle assessment (LCA) data is scarce, hindering a complete understanding of their overall environmental impact. This lack of data highlights the critical need for proactive change.

Analyzing the Environmental Risks: A Closer Look

The following risk assessment matrix compares the environmental impacts of different weight materials, considering manufacturing, supply chain vulnerability, and material degradation:

| Material | Environmental Impact | Supply Chain Risk | Material Degradation |

|---|---|---|---|

| Cast Iron | Moderately High | Low | Low |

| Fabricated Steel | Moderately High | Moderate | Moderate |

| Recycled Steel | Relatively Low | Moderate | Low |

| Composite Materials | Relatively Low | High | Moderate |

This matrix suggests that while recycled steel provides a more sustainable choice, the limited availability of composite materials currently poses a significant supply chain challenge. Further research is needed to optimize material selection, balancing environmental performance with cost-effectiveness and accessibility.

Sustainable Solutions: A Brighter, Greener Future

Several strategies can significantly mitigate the environmental burden of tractor weights:

1. Weight Optimization: Efficient weight distribution is paramount. Properly balancing weight on a tractor improves fuel efficiency, directly reducing fuel consumption and greenhouse gas emissions. Even distribution minimizes strain on the tractor's engine. Further research could establish optimal weight distribution parameters for diverse tractors and farming tasks.

2. Sustainable Materials: Recycled steel offers a more environmentally responsible option, reducing reliance on new resource extraction. While composite materials hold promise for significant weight reduction and enhanced fuel efficiency, higher upfront costs and supply chain vulnerabilities necessitate further research and development to address these limitations.

3. Lifecycle Management: Implementing a robust recycling infrastructure for tractor weights is crucial. Government incentives could stimulate investment in and adoption of comprehensive recycling programs. This supports the transition to a circular economy, where waste becomes a valuable resource.

Collective Action: What Each Stakeholder Can Do

Transitioning to sustainable practices requires collaboration. Specific actions for key stakeholders include:

Farmers: Optimize weight distribution to improve fuel efficiency. Prioritize regular maintenance to extend the lifespan of equipment and delay replacements.

Suppliers: Investigate and promote the use of recycled and sustainable materials. Transparent lifecycle assessments enhance product credibility and cater to growing market demand for eco-friendly options.

OEMs: Design modular weight systems adaptable to various tractor models, prioritizing sustainable materials and manufacturing processes. This demonstrates environmental responsibility and appeals to environmentally conscious customers.

Governments & Research Institutions: Fund research into innovative sustainable materials and effective recycling methods. Implement policies and financial incentives encouraging the adoption of sustainable practices.

The Path Forward: A Greener Agricultural Landscape

The continued demand for tractor weights presents a significant environmental opportunity. Through collaborative efforts and the adoption of sustainable solutions, the agricultural industry can minimize its environmental impact, enhance equipment longevity, and cultivate a greener future. Ongoing research and innovation are essential to achieve continuous progress.

How to Choose Sustainable Tractor Weights for Fuel Efficiency

Key Takeaways:

- Optimizing tractor weight improves fuel efficiency and reduces environmental impact.

- Different weight types (front, rear, wheel, suitcase, ballast box) have varying effects on traction and fuel consumption.

- Sustainable alternatives like recycled materials and optimized weight distribution deserve consideration.

- A holistic approach, considering the entire lifecycle, is crucial for sustainability.

Choosing the Right Weights: A Practical Guide

Selecting sustainable tractor weights involves a careful analysis of several factors: soil type, terrain, implement type, and tractor specifications. The goal is to achieve sufficient traction without compromising fuel economy or environmental sustainability.

Assess Current Needs: Begin by examining your current weight configuration. Can you achieve better distribution with your existing weights? Optimizing existing weights may eliminate the need for additional purchases.

Consider Sustainable Materials: Explore recycled steel as a more environmentally sound alternative to traditional materials. While potentially more expensive initially, the long-term environmental and economic benefits often justify the higher upfront cost.

Plan for Disposal: Collaborate with local recycling facilities capable of handling tractor weights. Proper disposal minimizes environmental harm and recovers valuable resources.

Implement a Holistic Approach: Success requires a comprehensive strategy that integrates weight optimization, sustainable material selection, and responsible lifecycle management.